Probing Effects of Dissipative Processes on Spall Failure of Materials

To be funded by: NNSA/SSAA; Faculty: Thadhani and Kacher

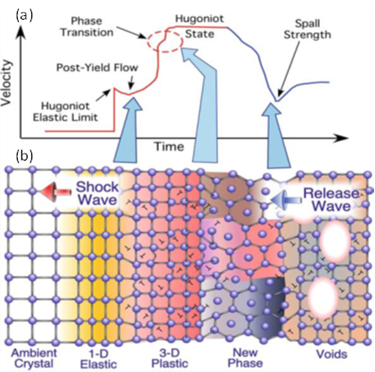

This project includes experimental investigations aimed at probing the influence of mesoscale structure on shock wave dissipation and spall failure in AM fabricated single and mixed phase Ti5553 and compositionally graded Ti-Ta alloys. The specific objectives include generating microstructures through controlled heat treatment of additively manufactured beta-phase Ti-5Al-5V-5Mo-3Cr and compositionally-gradient Ti-Ta alloys; determining the extent of shock wave dispersion/disruption caused by competing modes of plasticity via martensitic/twinning transitions or dislocation-mediated slip; establishing effects of dissipative processes on strain-rate strengthening/softening in microstructurally complex Ti alloys and their influence on spall failure strength and damage; and mapping process-structure-property-performance through effects of pre-existing and evolving microstructure on dissipative processes and resulting spall failure properties.

Gas gun plate-on-plate impact instrumented and soft-recovery experiments using multi-sample target assemblies with designs informed by computational modeling (ensuring uniaxial-strain loading). Time-resolved optical, interferometry, and x-ray diagnostics will be used to elucidate the spatiotemporal evolution of dissipative processes associated with shock-induced competing modes of deformation occurring via dislocation mediated slip, or martensitic/twinning transformations, and wave interactions with interfaces, and their effects on spall failure. Microstructure characterization of soft-recovered samples will also be performed correlating measured properties with structural changes at various length scales.